Reimagining manufacturing for Hyster® A Series lift trucks

For the new Hyster® A Series lift trucks, Hyster revolutionised its manufacturing process to deliver the tough, high quality lift trucks that you expect, built around the particular needs of the intended application and the operator. That’s why this series is described as ‘Distinctly Hyster, built for you’.

With A+ Logic at the core, Hyster A Series lift trucks can be easily configured to fit each customer’s unique needs, straight from the factory. Watch this video to see how H2.0-3.5A lift trucks from the Hyster A Series are manufactured at the Hyster site in Craigavon, Northern Ireland.

Transforming production lines at the Hyster factory

Quality products are always the desired end result of the manufacturing process at the Craigavon factory. Achieving the highest manufacturing efficiency and quality results from incremental improvements. Hyster has made significant investment [ML1] in these steps to make the process better and better.

With the new scalable A Series lift trucks, the Hyster factory has been updated with production lines designed to be flexible and agile. The latest updates to the factory will also see Hyster build both IC and Electric trucks in the same line space. This offers more adaptability and, in turn, improved responsiveness for customers’ requirements.

The manufacturing transformation also provides consistency across all the product ranges that Hyster builds, so that the highest quality product is delivered, and standards are maintained even though there are more models to assemble.

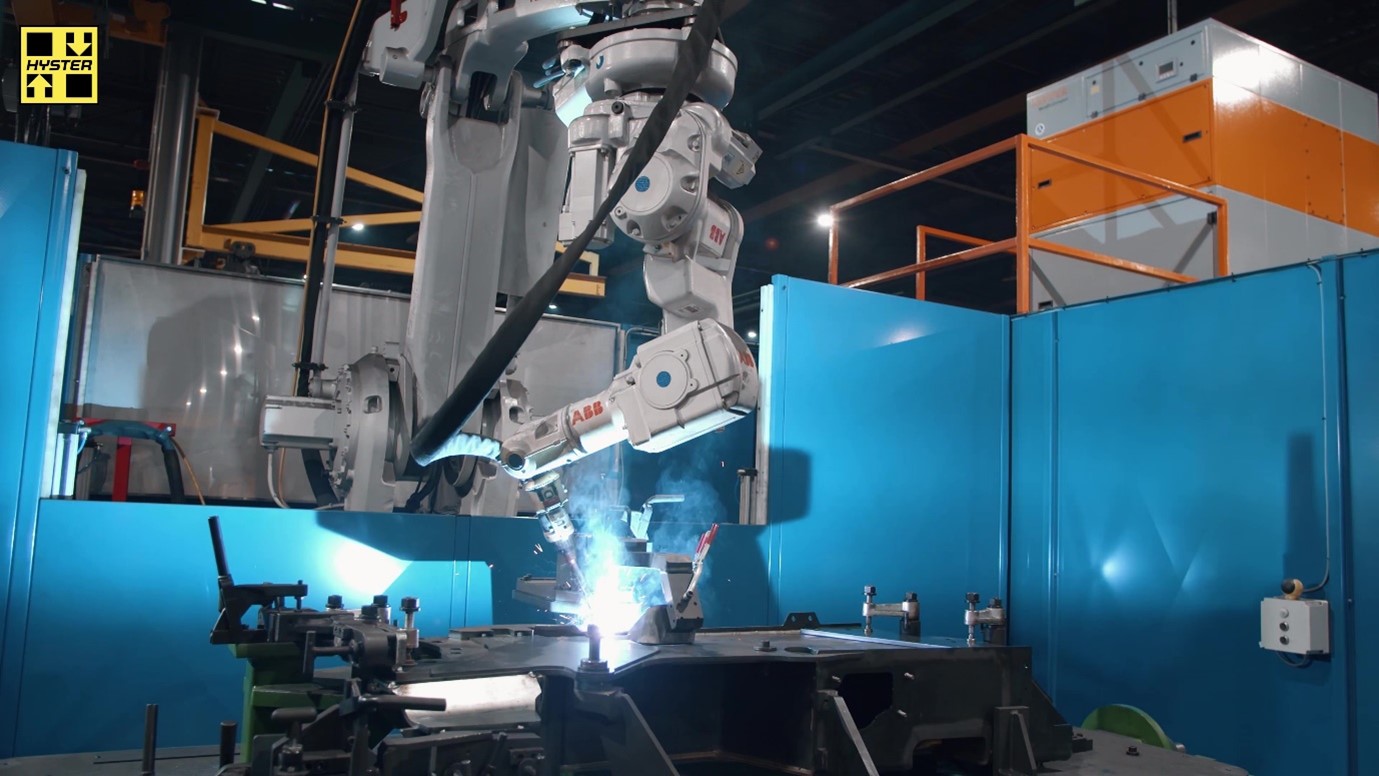

New technologies and processes have been introduced to help improve quality in manufacturing and assembly. These include welding robots, manipulators of automated torque tool, electronic QA checklists, and the move to supermarket kitting.

The new Hyster production lines have also been designed to reduce non value-added activity. For instance, technologies such as AGV trollies that return automatically have been introduced. This allows production line operatives more time to focus on training and completing their daily tasks with high accuracy.

As part of this virtuous circle, product design plays a role. On the new production line, there will be more component commonality between ICE and Electric lift trucks than has ever been seen before at Hyster. This reduces part complexity.

Why change how Hyster trucks are made?

The new scalable design and manufacturing philosophy enables Hyster A Series forklifts to deliver superior performance for the specific operation as well as a low total cost of ownership. The new approach also makes it easy for customers to add the features that are needed for productivity in their operation and avoid paying for unnecessary options that increase cost without adding value.

Hyster has designed the new H2.0-3.5A lift trucks this way as no two customers face identical challenges. With the Hyster A Series, instead of providing you with options for a truck we already built, we build the truck you need according to your duty cycle, environment, and tasks.

Fine tune your forklift today

Learn more about the Hyster A Series or speak to your local Hyster dealer to place an order.