low level order picker

A NEW LEVEL OF INNOVATION

- Models

- LO55-80

- Capacity

- 5500-8000lbs

The LO55-80 order picker provides enhanced capabilities for both existing and planned facilities. In existing operations, it offers the opportunity for new slotting strategies and increased SKU capacity along with decreased travel path times without adding to the footprint of the warehouse. For new facilities there is the potential for a reduction in building costs with a smaller warehouse required to stock the same amount of SKUs. All of which adds up to a more productive, cost-effective operation.

- Productivity

- Ergonomics

- Durable Design

A new level of innovation

The dual technology combi-controller and AC traction motor increase energy efficiency and ensure that full capacity loads can be moved without an increase in energy consumption. This lift truck series can be tailored to your operation and designed to address the challenges of today’s ever-changing business climate. The low-level order picker leverages the capabilities of a conventional pick vehicle with the speed and efficiency of a pallet truck. The operator can easily access the 6-10 foot strike zone with increased safety and less effort.

The LO55-80 order picker can all but eliminate the need for a merge process. Efficient picking from multiple zones across a large warehouse often requires a pallet truck and high-level order picker. By slotting fast movers in the 0–6.5 foot range and dedicating the 6.5-10 foot range to slow movers and storage, the operation can be maximized for revenue per cubic foot and replenishment penalties can be minimized.

The LO55-80 series is specifically designed to help picking operators enjoy a reduction in fatigue and increase in efficiency. Intelligently engineered features reduce operational effort and the distance the operator has to reach when picking from rack to pallet, increasing efficiency and reducing fatigue.

POWER STEERING: Finger-tip control with power steering reduces the arm movement required to change direction while the design also allows the operator to remain within the footprint of the truck at all times for greater personal protection.

OPERATOR COMPARTMENT: The suspended platform area helps to increase operator comfort and allows easier pass through to optimize picking from both sides of the truck. The operator sensing floor mat covers the entire platform area to detect when the operator is on board. The optional lifting platform is foot controlled to facilitate ground and second level picking, reducing the distance the operator has to reach when picking from rack to pallet. This reduces fatigue and allows the operator to lift and lower hands free after second level picking.

CONTROL HANDLE: The optimized ergonomics of the control handle reduces arm movement required to change direction, allowing the operator to remain within the truck footprint at all times for protection as well as helping to reduce operator fatigue and increase productivity. The wraparound design keeps the operator’s hands within the interior perimeter of the handle and the large control buttons are conveniently positioned reducing fatigue and repetitive movement.

- Heavy duty frame for maximum strength

- O-ring face seals help eliminate leaks

- Sealed connectors on critical connections

- Robust pull rod design of load wheel axle ensures long term reliability

| Model | Load Capacity | Lift Height | Platform Height | Battery Capacity Voltage | Weight |

|---|---|---|---|---|---|

| LO55 | 5500lbs | 4.7 | 38.6 | 24V / 425-750Ah | 2888 |

| LO60 | 6000lbs | 4.7 | 6 | 24V / 425-750Ah | 1950 (36 in. forks) / 1955 (48 in. forks) / 2030 (60 in. forks) |

| LO80 | 8000lbs | 4.7 | 6 | 24V / 425-750Ah | 1995 (48 in. forks) / 2100 (96 in. forks) / 2250 (144 in. forks ) |

We would not be where we are today without one of the most professional dealer networks in the industry. We work hard to design and manufacture the best lift trucks, but it is our stellar dealers that bring it all together for you.

Dealers help at every step of the process

- Understanding your specific lift truck applications

- Recommending special features to improve your productivity

- Configuring the proper quotation

- Helping with financing options when required

- Prepping your truck for delivery after it leaves our factory

- Arranging for operator training

- Providing planned maintenance on your trucks

- Supporting National Accounts management

- Providing fleet management services, if needed

- Providing emergency service and parts

- Providing rental trucks at short notice

- Helping determine exactly when to purchase new lift trucks

The GSA creates a centralized location for the federal government, offering products, services, and facilities needed for federal agencies to serve the public. As a GSA certified company, Hyster supports the GSA’s mission to provide innovative solutions for federal agencies with cost-effective and high-quality products. You can also find more information on the General Services Administration at www.gsaadvantage.gov

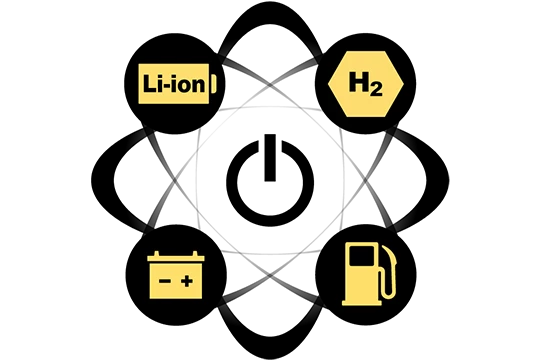

POWER YOUR POSSIBILITIES

HYSTER POWER MATCH

Not all power is the same. Learn how a better-matched power source could make a difference in your operations.

OPERATOR ASSIST SOLUTION

FORKLIFT FLEET INSIGHTS & CONTROLS

Hyster Tracker forklift telemetry provides true wireless fleet management, equipping operations with actionable insights to drive fleet efficiency, improve operator performance, reduce carbon emissions and lower overall materials handling costs. Wireless monitoring, the base level of Hyster Tracker, comes standard on all A Series models.

HYSTER POWER CELLECT

CHANGE AMONG FORKLIFT BATTERY TYPES

What if you could install one battery source into your lift truck, then have the flexibility to change that battery source at any time? Now you can, with Hyster Power Cellect™, a one-of-a-kind, flexible power solution.

The truck is only part of the solution

Hyster knows that a tough truck, is even better when it comes with a strong partner to meet your unique needs.