Downloads

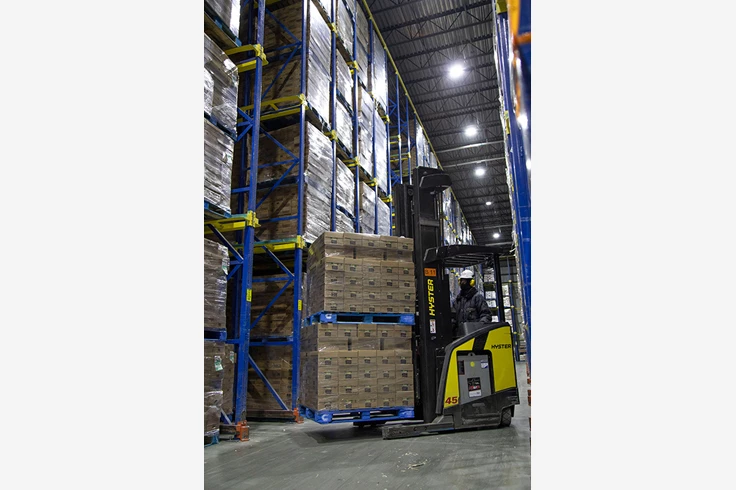

- NZR3-NZDR3-NZDR3NZRS3-NZDRS3 Reach Truck Brochure

- NZR3-NZDR3NZRS3-NZDRS3 Reach Truck Sales Flyer

- NZR3-NZDR3NZRS3-NZDRS3 Reach Truck Sales Flyer SPA

- NZR3-NZDR3 Reach Warehouse Tech Guide.pdf

- NZRS3-NZDRS3 Retail Reach Tech Guide

- Hyster Posture Relief Flyer

- Hyster Special Equipment Brochure

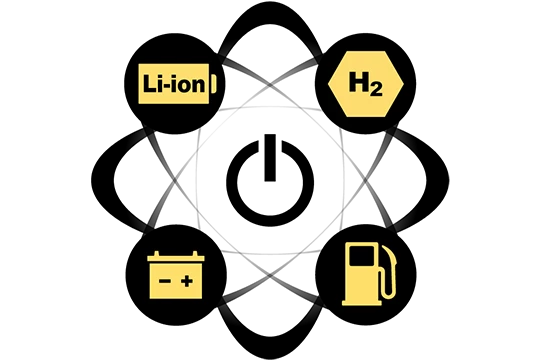

- Power Cellect Sales Flyer